While engaging extensively in our daily activities, we can’t even live a day without technology in this era. One of these technologies includes optoelectronics, which is present in almost all our daily gadgets and several industrial practices – from smartphones to infrared lasers. A study shows that the optoelectronics market was at USD 6.54 billion in 2022, which is predicted to scale to around USD 21.2 billion in 2023, making a CAGR of 12.48%[1]. It emphasizes itself as great business opportunities and as a necessity in our lives. During this progress, hermetic packaging, used in optoelectronic devices, is a cornerstone of its diverse properties and affirms its right functioning, triggering the development of optoelectronics.

With time, several types have been introduced to make hermetic packaging more flexible to specific applications and requirements. One of these types is laser butterfly designs, which are majorly relied on for high-capacity performance. Let’s cut to the chase and find how laser butterfly design is an exceptional choice for optoelectronics.

Benefits of Laser Butterfly Structure in Hermetic Packaging of Opto-Electronic

- Protection from External Components

Since optoelectronics has made its way to more technological space, it is used under very complicated or aggressive procedures where thermal energy is produced. For obvious reasons, the microelectronics can’t bear it unless it’s sealed with a fighter.

The essence of laser butterfly packaging lies in its capability to fortify sensitive electronic parts within a shielded enclosure, safeguarding them from the hostile external environment. By creating a protective barrier against dust particles, microorganisms, and elevated temperatures, the lase butterfly packaging technique ensures the longevity and optimal functioning of the enclosed optoelectronic components.

- Prevention of Oxidation and Corrosion

A laser butterfly package is not a cookie-cutter design that only seals the internal components and lets it work free of dust or germs. As the pacesetter of modern equipment standards, optoelectronics communication systems are also used under the ripples of the ocean or in the silence of space.

Needless to say, these atmospheres can pollute the devices with loads of humidity, water, and organic matter with corrosive agents. For that issue, the laser butterfly packaging works as a shield to maintain the components and operate without being destroyed by corrosion or oxidation.

- Customization of Specific Needs

Each application of optoelectronics communication requires a distinct space or adjustment to support innovative and lifeblood operations worldwide. These operations often require devices to be lightweight and carriable size for robust performance, which demands the packaging of components to be indubitably specific for that particular device.

The Secret Behind the Power of Laser Butterfly Packaging When Sealed

- Deliver Compact Design

The internal components of micromachines are ensured to be adjusted in a size that can be used seamlessly and in a limited space. In this case, the laser butterfly packaging design enables the devices to function invincibly where the hermetic packaging is used under the OCT systems or optical Fiber Gyroscopes, whose efficiency depends on size and weight.

- Enhance Alignment Stability

The laser butterfly design makes it easy to opt for hermetic packaging for its conventional structure that ensures an alignment that can transfer the optoelectronic communication signals, enhancing the exact and smooth operation.

- Optimize Thermal Management

A typical diode laser produces up to 60W as waste heat when 100W output power is provided[2]. Therefore, cooling mechanisms are used within these applications, but the heat shock may eventually melt down the internal components. Fortunately, a butterfly package prevents these circumstances thanks to its thermal resistance, which absorbs the heat and safeguards it from temperature-induced damage.

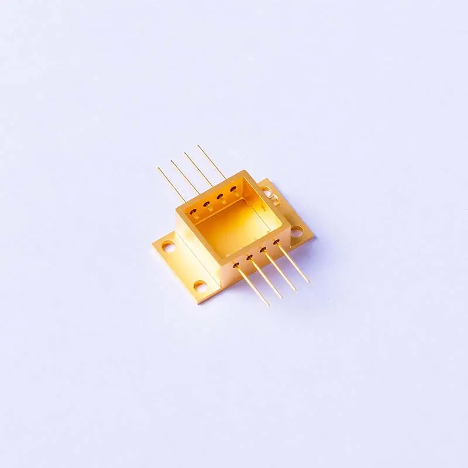

Hermetix Laser Butterfly MDFO1413-w8 – An Epitome of Resistance

We, Hermetix, have released state-of-the-art optoelectronic packaging where glass-to-metal seal packages, specifically in the laser butterfly packaging. It can be widely considered for many devices. Our laser butterfly hermetic product, MDFO1413-w8, is explicitly compatible with optoelectronic components in a sensitive environment while reducing the cost of protection. Here are some of the main features of this product:

- Reliable Structure

The packaging has 8 leads with flattened wire and 2 main leads, a design that harmoniously connects the internal components with the whole device system.

- Protection

The seal of this product is glass to metal, which guarantees the protection of hermetic packaging from any contaminants, temperature fluctuations, dust, or germs.

- Customization

The product comes with a PIN pitch of the leads that can be customized according to the design of the optoelectronic components and an option of selection from numerous housing structures to adjust to specific requirements.

Conclusion

Lastly, after evaluating the importance of laser butterflies for hermetic packaging, it’s evident that the increased use of technology in all aspects of life has also raised the need for perfection in the tiniest functions. The root of each system has to be secured and adjusted well enough to let optoelectronics communications pave their pathway without any hurdle.

Since laser butterfly packaging and other types of hermetic packaging are essential parts of the progress of optoelectronics technology, Hermetix has stepped forward and achieved recognition for a pool of microelectronic packaging products. Our professionals stand tall for providing the most integral solutions for developing industries, such as automotive, data centers, and biotechnology, ensuring the quality and efficiency of optoelectronic components. If you are interested, please visit our Hermetix official websites to get more information!

Reference

- Available at: https://www.precedenceresearch.com/optoelectronics-market

- Available at: https://ieeexplore.ieee.org/document/4160896