Main Features

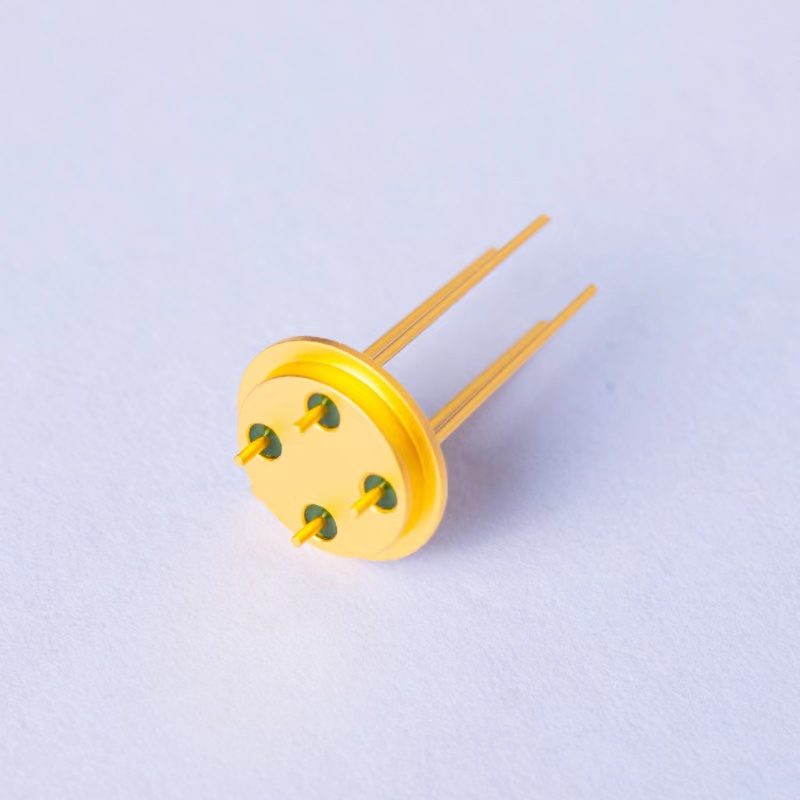

- High production efficiency because the housing structure is formed by mechanical stamping process

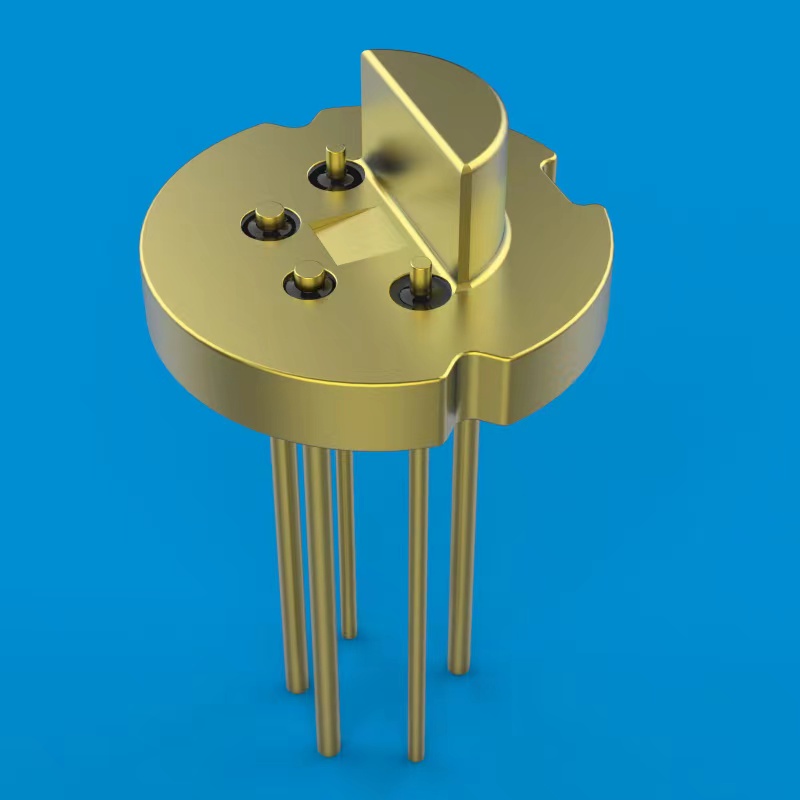

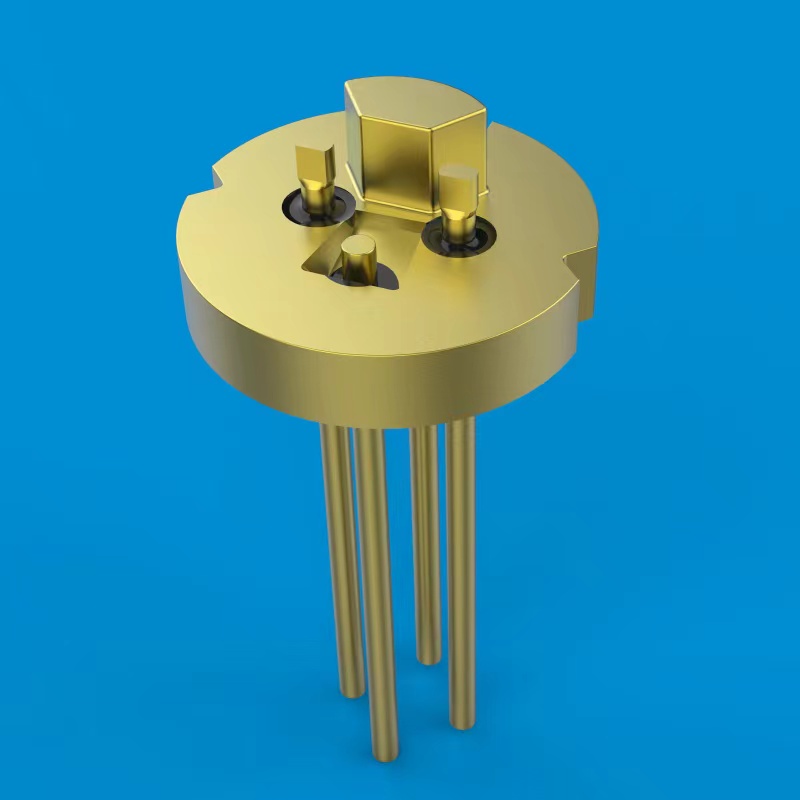

- Customized shapes of this sensor header

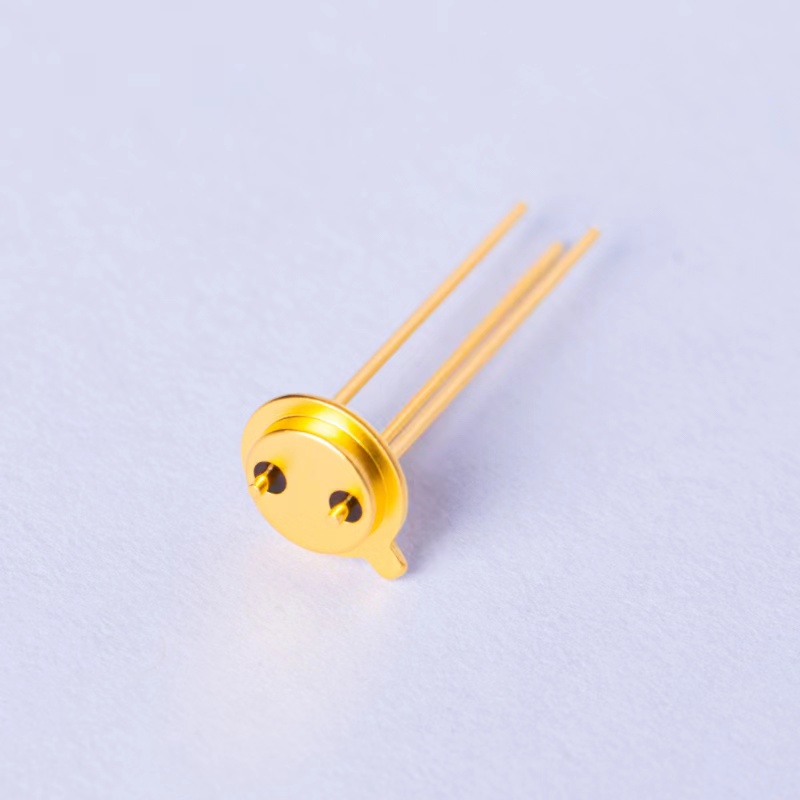

- Two main leads of this to 46 header to satisfy your needs

- Innovative lid sealing methods to ensure its performance

- Multiple plating options to guarantee various applications

- Customization is the best way to fulfill your specific requirements