- The Gold-Tin Lid Series showcases the remarkable power of explosive cladding, revolutionizing hermetically sealed electronic packages

- These innovative lids fuse different materials through controlled explosions, resulting in unmatched bonding strength and sealing performance

- With the Gold-Tin Lid Series, you can unlock superior hermetic packaging solutions that ensure maximum protection for your critical components

- The explosive cladding redefines the standards of hermetic sealing in the electronic industry, so as to allow you to experience the pinnacle of reliability and performance.

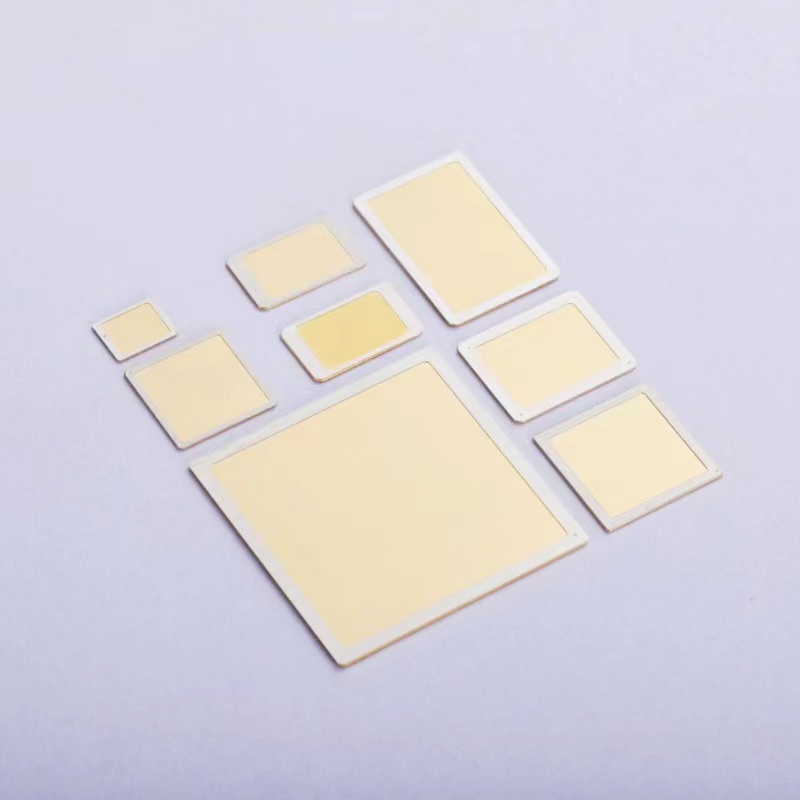

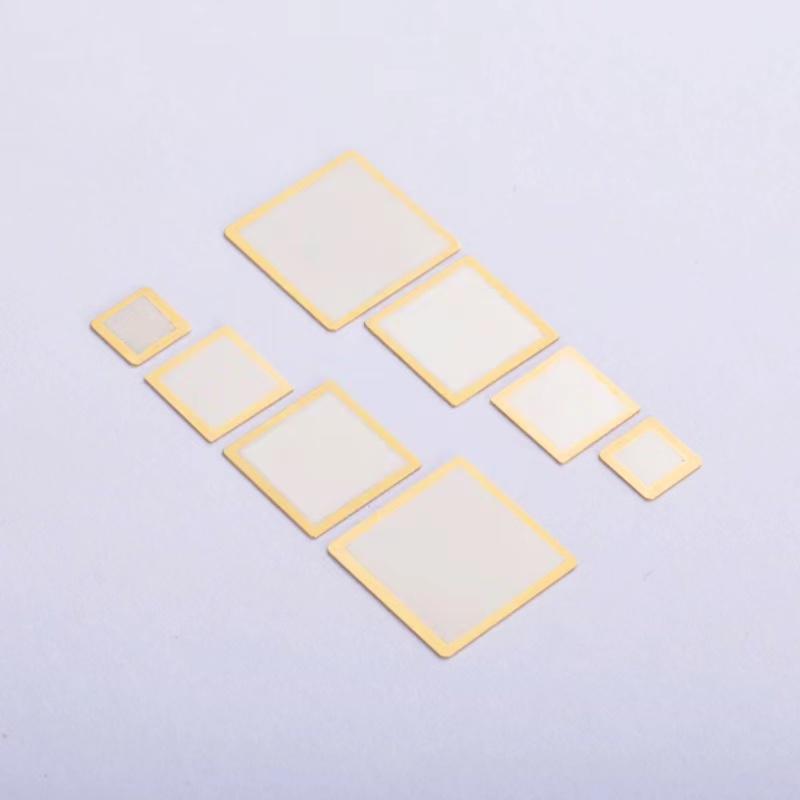

Gold-tin lid series (cladding)

Description

Gold-Tin Lid Series Information

The Gold-Tin Lid Series with explosive cladding offers unrivaled advantages in hermetically sealed electronic packages and hermetic packaging solutions. Its explosive cladding technology ensures superior bonding strength and sealing performance, guaranteeing the utmost protection for critical components.

Main Application

Its exceptional capabilities make it highly sought after in various applications. From hybrid integrated circuits to semiconductor integrated circuits, filter devices to microwave devices, high-power devices to connectors, and sensors, the Gold-Tin Lid Series is widely utilized.

Why Choose Hermetix?

Hermetix, one of the most trustworthy glass-to-metal seal manufacturers, is always dedicated to providing customers with the best quality hermetic packages worldwide. Being a metal packaging manufacturer in this field for decades, we know exactly what you want and will endeavor to satisfy your specific needs. Get to learn more about us:

- Customized Design Communication Pioneer

- Standard Quality Assurance

- Safe Shipping

- Professional After-Sales Service

| Composition | Materials |

| Preset Solder Composition | Au80Sn20 |

| Lid material | 4J29, 4J42, molybdenum copper, ceramic, etc. |

| Lid plating | Ni/Au, Ni/Au/Ni/Au/ |

With over two decades of experience helping clients move from prototype to commercialization, Hermetix customized engineering service offers immense value at the R&D stage. From material selection to pin configuration to sealing techniques, our engineers can provide various solutions to help you overcome the technical obstacles our clients face in the early phases of designing a new product. We can work from your drawings or ours while pinpointing ways to lower costs and improve functionality.

Customization Process

Hermetix Hermetix Optoelectronic Packaging process includes the following steps

Step 1: Understanding Client Needs

Hermetix engineers collaborate with clients to identify the project’s technical requirements and end-use.

Step 2: Design the Optoelectronic Packaging

Hermetix engineers draft technical drawings focusing on workability from the productions’ point of view and end-user, e.g., bonding and sealing requirements.

Step 3: Monitoring Production Progress

Hermetix keeps track of suppliers’ manufacturing processes, including updating clients on progress and ensuring lead times.

Step 4: Inspection + Shipping

Once products are finished, Hermetix will verify product compliance and ship.

Step 5: After-Sales Services

Hermetix ISO 9001 – Certified Quality Assurance team follows standardized procedures to address and remedy any quality issues immediately.